Today Modern is equipped to keep pace with contemporary global developments and market demands. we are engaged in providing a high quality range of Generator Rental Services pan India. In the years ahead, Modern venturing into newer horizons, modernized Fleet of equipment’s, state of the depots with sound experience & unmatched marketing & engineering skills, envisions itself to be the leading player in Indian Power Rental Industry.

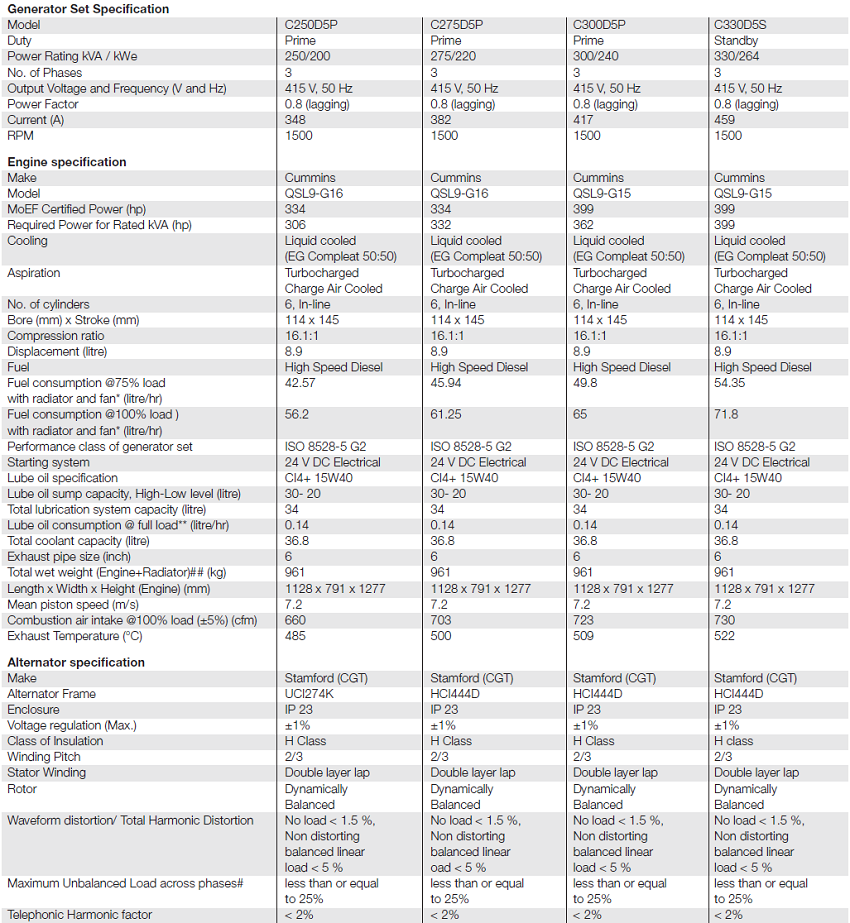

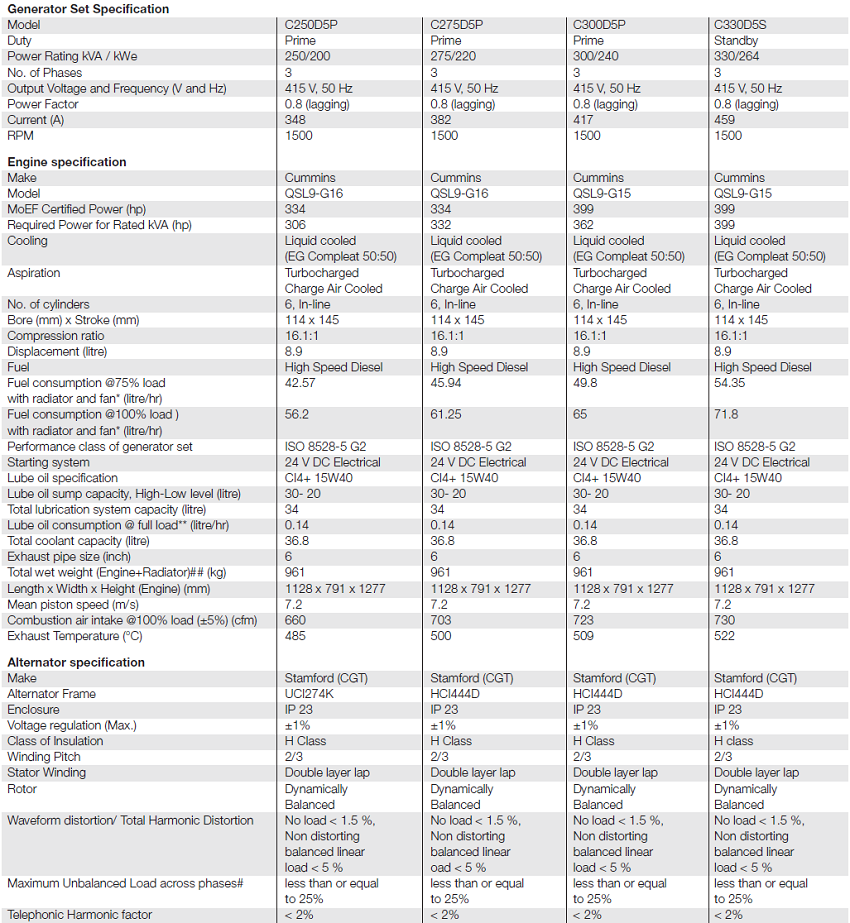

Genset - 380 KVA Specification

Make: Cummins India

264 KWE, Standby

Engine

- Cummins QSL9 series, 6 cylinder, In-line 4 stroke, radiator cooled engine

- Full Authority Electronic Engine

- Well designed air handling system with

- Dry type, Replaceable paper element air cleaner with restriction indicator

- Air to air aftercooling

- Optimised turbocharger for increased altitude capabilities

- Best in class fuel economy with

- Bosch HPCR fuel system with A1 class electronic governing

- Dual fuel filter system: Pre filter including water separator and Water In Fuel (WIF) sensor and main filter

- Electrical lift pump for faster response

- Standard integral set-mounted radiator system, designed and tested for 50°C ambient temperature

- Full flow spin on lube oil filter

- Plate type lube oil cooler

- First fill of lube oil and coolant

- Electrical starter motor with soft start engagement feature

- Battery charging alternator

- 2 X 12 V DC battery

Alternator

- Stamford UC27 and HC4 alternator frames from Cummins Generator Technologies

- Brushless type, Screen protected, Revolving field, Self excited alternator conforming to IS/IEC 60034-1

- 3 Phase reconnectable winding with 12 terminals brought out for connection

- Better motor starting capability

- Best in class efficiency

- Compact design with sealed bearings for longer life and lesser maintenance

- Impregnation on all wound components for better mechanical strength

Control Panel

Control panel is manufactured with 14/16 gauge CRCA sheet and is powder coated for weather-proof and long lasting finish.

The control panel consists of the following parts:

- PowerCommand 1.2 Controller

- Aluminum bus bars with suitable capacity with incoming/ outgoing terminals

- Indicating lamps for ‘Load ON’ and ‘Set Running’

- Instrument fuses duly wired and ferruled

- MCCB of suitable rating with overload and short circuit protections

PowerCommand 1.2 features

The PowerCommand® control system is a microprocessor based generator set monitoring, metering and control system with LCD display designed to meet the demands of today’s engine driven generator sets

- Intuitive operator interface which includes LED backlit LCD display with tactile feel soft-switches & generator set status LED lamps

- Digital AVR for shunt or PMG excitation with torque matching.

- Digital electronic governing with temperature compensation

and smart starting.

- SAE J1939 interface to Full Authority Electronic (FAE) engines.

- Remote start-stop

- Engine metering: Oil pressure, Coolant temperature, Battery voltage, Engine speed

- AC Alternator metering: L-L Voltage and L-N Voltage, Current (1 and 3 phase), Volt-Amperes (phase and total) and Frequency.

- Engine protection: Low lube oil pressure, High/Low coolant temperature, Over speed, Battery Over/Under/Weak Volts, Fail to crank/start, Sensor failure.

- AC Alternator protection: Over/Under voltage, Over/Under frequency, Over current, Short circuit and Loss of AC sensing.

- Data logging: Engine hours, Control hours, Engine starts and upto 10 recent fault codes

- Configurable glow plug control

- Configurable cycle cranking

- 12 and 24 Volt DC operation

- Sleep mode

- Programmable I/Os (4 inputs and 2 outputs), expandable with AUX101/102 modules

- Modbus interface (RS485 RTU)

- InPower compatible (PC based service tool)

- Certifications – meets the requirement of relevant UL, NFPA, ISO, IEC, Mil Std., CE and CSA standards

Silencer

Hospital grade silencer suitably optimized to meet stringent noise emission standards laid down by MoEF / CPCB

Mounting Arrangement

- Engine and alternator are mounted on a common MS fabricated base frame with AVM pads.

- Base frame with integral fuel tank is provided with drain plug, air vent, inlet and outlet connection, level indicator and provision for cleaning

Optional

- Engine: Coolant heater, Oil drain pump, Heavy Duty air cleaner

- Alternator: PMG

- Control Panel: PC3.3, Microprocessor / Relay based AMF control panel

- Others: Mobile sets with canopy

Technical data

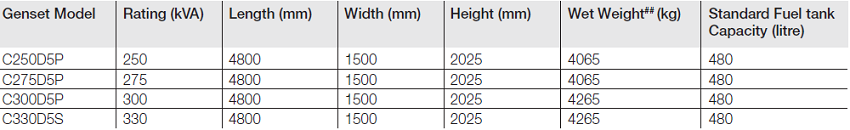

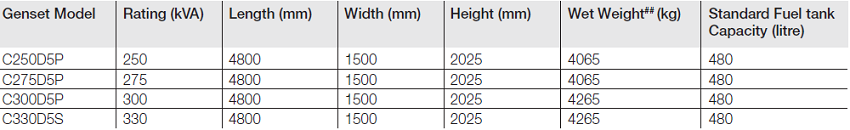

Typical Enclosed Genset Dimensions